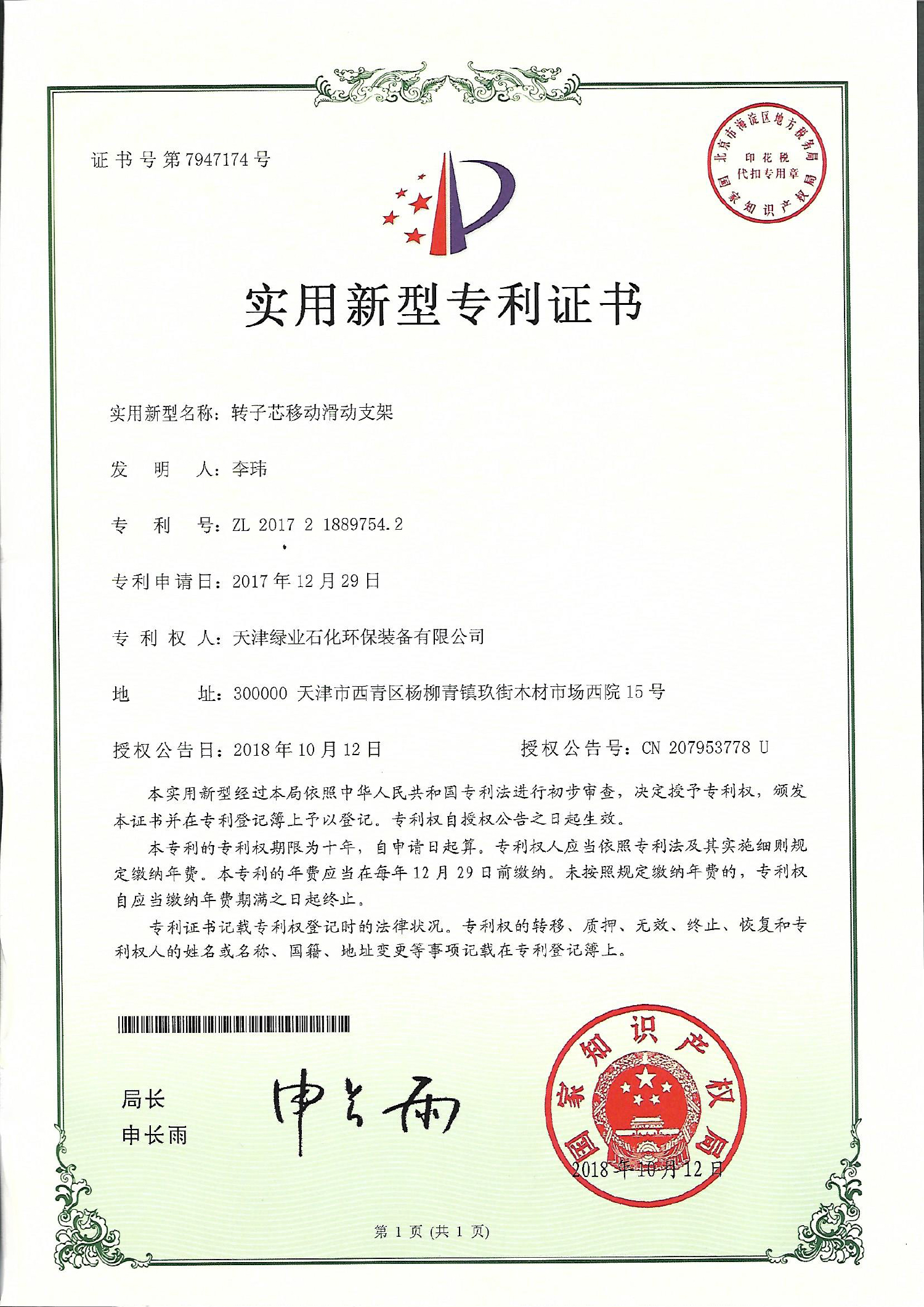

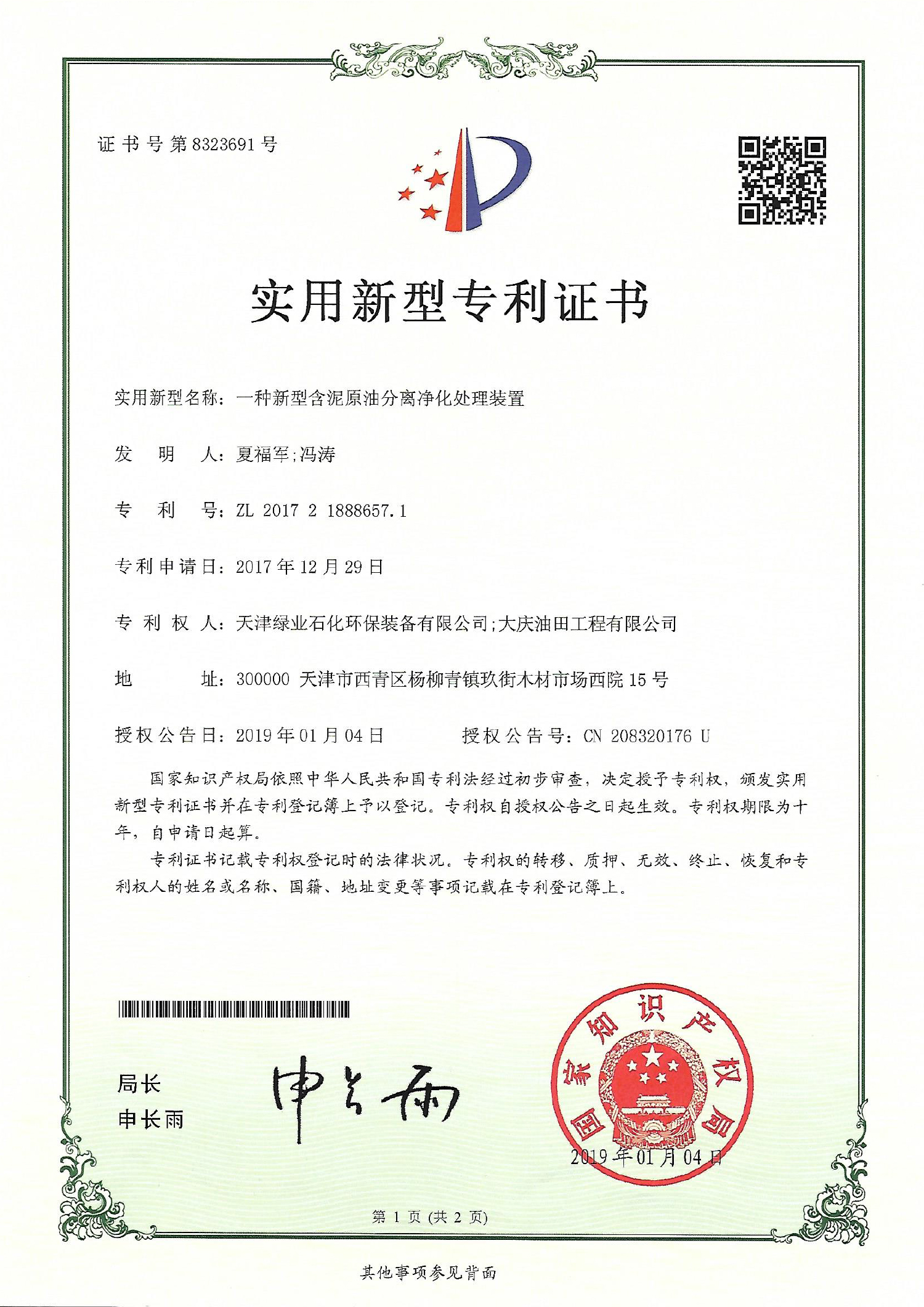

Green Industry "is a national high-tech enterprise that integrates" industry, academia, and research "collaborative innovation. It focuses on customized research and development of non-standard equipment and integrated development of advanced technology and process packages. Its core business focuses on process integration, energy conservation, comprehensive utilization of waste heat, and resource utilization. We rely on the profound academic background of research institutions such as Tianjin University and Hebei University of Technology to build a solid research and development foundation. We have accumulated more than 30 independent intellectual property patents and participated in the establishment of a research institute with waste heat energy conservation and resource utilization technology as the core specialty. The main service areas of the product cover industries such as petroleum, refining, and chemical engineering, especially in the field of fine chemicals, which has been deeply cultivated for many years.

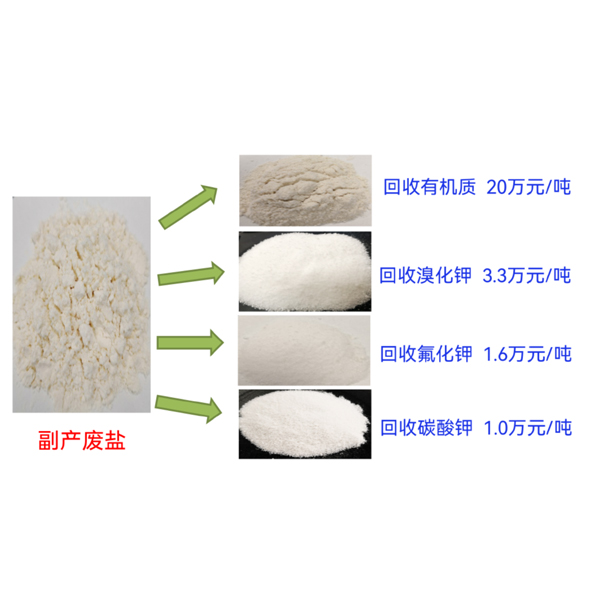

Based on its own core research and development capabilities and technology, "Green Industry" has successfully developed and industrialized a series of key equipment, including process gas twin-screw compressor systems, twin-screw steam compressor heat pump systems, and twin-screw multiphase mixed flow rotor pump systems. These system solutions have been widely applied in industries such as petroleum, refining, chemical, environmental water treatment, and steel. They are the first tier suppliers of large petrochemical and chemical companies such as PetroChina, Sinopec, CNOOC, and Shenghong Petrochemical. Has successively been awarded the title of "Innovative Enterprise" by Tianjin City, as well as honorary qualifications such as "National High tech Enterprise" and "National Innovative Small and Medium sized Enterprise". At the same time, long-term industry university research cooperation relationships have been established with multiple research institutes such as the National Distillation Center of Tianjin University, the National Key Local Joint Laboratory of Hebei University of Technology, and the Desalination Institute of the Ministry of Natural Resources. At present, we have obtained more than 30 proprietary intellectual property patents and inventions, and have passed multiple authoritative system certifications. The R&D team is composed of more than 20 multi-disciplinary technical members led by 3 PhDs and 4 masters. A team that combines old, middle, and young members exhibits a vibrant and enterprising spirit, as well as youthful, professional, and skilled characteristics. The R&D team has developed multiple bromide and lithium salt crystal form control and high salt waste liquid resource chemical process packages, and multiple projects have achieved engineering industrialization. The application in the synthetic raw material pharmaceutical industry has achieved significant economic benefits for the production side.